Table of Contents

- Table of Contents

- 1.0 Purpose

- 2.0 Manufacture of Platinum Dioxide

- 2.1 Discussion

- 2.2 Review of alternative procedures

- 2.3 Equipment

- 2.4 Chemicals

- 2.5 Dissolution of Platinum in Aqua Regia

- 2.6 Oxidation of Ammonium Chloroplatinate to Platinum Dioxide

- 3.0 The Hatch-Feinstein Reduction

- 3.1 Discussion

- 3.2 Test-vessel construction

- 3.3 Pre-reduction of platinum dioxide

- 3.4 Primary reaction vessel construction

- 3.5 Reductive amination of P2P using Adam's catalyst

- 4.0 Manufacture of 1-phenyl-2-propanone

- 4.1 Equipment

- 4.2 Chemicals

- 4.3 Production of 1-phenyl-2-nitropropene

- 4.4 Reduction of 1-phenyl-2-nitropropene to 1-phenyl-2-propanone

- 5.0 Manufacture of Methylamine from Formaldehyde and Ammonium Chloride

- 6.0 Manufacture of 70% Nitric Acid

- 7.0 Laboratory Equipment and Procedures

- 8.0 Keeping Out Of Trouble

1.0 Purpose:

To describe the manufacture and application of platinum dioxide, commonly known as Adams catalyst or platinum black, with the goal of opening alternative synthesis procedures for the manufacture of illicit recreational drugs. It is this writer's hope that these procedures will result in the undermining of the Drug Inquisition, which has caused the loss of freedom for many good people. A further goal is to demonstrate to those in law enforcement that knowledge is, in fact, the ultimate power and that no number of self-righteous goons with guns can defeat a resourceful and knowledgeable mind. There is no new chemistry here; in fact, most of it is almost 100 years old. The contribution this writer hopes he is making is in simplifying the equipment and procedures to the point where those without extensive chemistry backgrounds will be able to manufacture high-quality phenethanamines in high volume to compete with the poisonous stuff one finds on the street. The text is aimed at those who have completed a college level organic chemistry course and have some experience and an interest in laboratory equipment and procedures.

1.1 Scope

The following procedures will be described.

- Dissolution of platinum metal in aqua regia to produce chloroplatinic acid, then ammonium chloroplatinate.

- Oxidation of ammonium chloroplatinate to platinum dioxide.

- Reductive amination of P2P using platinum dioxide catalyst.

- Manufacture of methylamine using formaldehyde and ammonium chloride.

- Manufacture of 1-Phenyl-2-Propanone using benzaldehyde and nitroethane.

- Practical manufacture of 70% nitric acid

1.2 Acknowledgements

This writer thanks Uncle Fester, whose widely read books on methamphetamine manufacture have provided an invaluable source of research information collected in one volume. In addition, this writer thanks Dr. Alexander Shulgin, whose practice of the purest sort of science-that motivated by curiosity and a deep thirst for knowledge-in the face of government oppression has earned him my deepest admiration and respect. This document is dedicated to Senators Orrin Hatch and Diane Feinstein, whose tireless efforts to eliminate the vestigial remains of our civil liberties in the cause of state expediency has pissed me off enough to take the time and effort to produce this text. In fact, I have named the reductive amination step the Hatch-Feinstein Reduction.

2.0 Manufacture of Platinum Dioxide

2.1 Discussion

As those familiar with clandestine drug manufacture are aware, the traditional catalysts used in reductive amination procedures, Raney nickel and palladium-on-carbon, are no longer available due to essential-chemical prohibition by the anti-drug thugs. Thus the need for an alternative catalyst which can be manufactured utilizing common materials and equipment. Platinum dioxide has many advantages in it's application to reductive aminations:

It can be made using common materials and easily obtainable equipment.

Reactions are performed at room temperature and at low pressure (<30 psi), thus eliminating the requirement for simultaneous heating and agitation and opening the door to simple high-volume manufacturing. One can easily perform 25-30 mole reactions using a 5 gallon paint shaker for agitation.

- The catalyst is reusable up to six times.

- Requires a catalyst density of only 1g/mole of precursor.

- Provides a product yield of approximately 1kg/g of catalyst, and a 75% mole-to-mole yield from precursor-to-product (the reaction yield is 90%, the balance being lost during processing and crystallization) when manufacturing methamphetamine.

- Is used with common ethanol solvent, eliminating odd smells and fire hazards.

- Platinum dioxide catalyst also performs well in the manufacture of methylenedioxymethamphetamine (MDMA), but under slightly different conditions.

2.2 Review of alternative procedures

We will focus upon the manufacture of methamphetamine due to the current high volume requirement and the increasing attention it is drawing from the government antidrug machine.

- The best route for manufacturing methamphetamine is the direct reduction of the hydroxyl on the L-ephedrine sulfate sidechain in glacial acetic acid using 70% perchloric acid as a promoter and 5% palladium-on-carbon as the catalyst. Vigorous agitation, pressurization with hydrogen to 30 psi, and heating to 90°C results in an 85-90% yield of non-racemic methamphetamine, with a 70% yield-to-product. Due to it's non-racemic chirality, this meth is stronger than that produced by any other non-stereospecific reduction technique. Typically, this reaction is performed in a 4000ml filter flask placed into a 6 gal aluminum pot containing water. The pot is heated on a stirring hotplate and agitation is provided by a stirring bar magnetically coupled through the non-ferrous aluminum. A solution of 1.25 liters of glacial acetic acid, 120ml of 68-72% perchloric acid, 166g (one mole) of L-ephedrine sulfate, and 16g of 5% palladium-on-carbon is pressurized to 20-30psi with hydrogen gas and reduced for 2-3 hours. The catalyst is filtered out, the filtrate made basic with 50% lye solution then extracted with toluene and stripped of solvent, the base is purified by distillation and crystallized in acetone for the hydrochloride salt. Despite what has been written by others, this reaction does not work with ephedrine hydrochloride because the hydrochloride ion poisons the catalyst, whereas the sulfate ion may actually act as a promoter (I have not tried it, but in theory sulfuric acid may be substituted for perchloric acid as a promoter). This reaction will, however, perform well using any ephedrine base. Due to the requirement for simultaneous heating, stirring, and pressurization, this reaction is limited to 1-3 mole batches. In addition, the palladium-on-carbon catalyst is not reusable without processing.

- The most common current method of meth production is the direct reduction of the ephedrine hydrochloride hydroxyl using 57% hydriodic acid and red phosphorous in a 4-1-1 formula (4 lb ephedrine, 1 gal 57% hydriodic acid, 1 lb red phosphorous). This is an inefficient method, yielding 55% d-methamphetamine at the very best, which has been exploited as far as it can go due to the attention paid to the precursor and essential chemicals used in this reaction and the increasing diversion of Chinese ephedrine supplies to our industrious neighbors in Mexico. In it's favor, however, is the fact that one person can manufacture 4 lb of very poisonous meth per day if they skip the purification step. This is a perfect example of Gresham's Law at work (the cheap bad stuff drives out the expensive good stuff).

- The P2P reaction, for many years the preferred method for making methamphetamine, requires 1-Phenyl-2-Propanone (impossible to buy, easy to make), 40% methylamine solution (impossible to buy, easy to make), large amounts of Raney nickel (hard to buy, difficult to make) and approximately 2000 psi of hydrogen along with simultaneous agitation and heating. There are many limitations in this process, not least of which is equipment construction. [This is a very limited truth, as there are many other ways of reductively aminate P2P with methylamine which uses much more readily available materials than Raney-Nickel/hydrogen gas /Rhodium]

- The lithium-in-ammonia reduction. This is an elegant, high-yield reduction, but it is gawdawful stinky and must be done a long way from civilization. The volume of anhydrous ammonia required per mole of ephedrine relegates this procedure to the low-volume category.

2.3 Equipment

The following equipment is required:

- A stirring hotplate.

- A 2" Teflon-coated magnetic stirring bar with a center lifting ridge. This is simply a ridge around the center of the stirring bar that raises it above the bottom surface, thus decreasing friction and providing for easier stirring of thick solutions/suspensions. A 2.5-3.0" stirring bar will also be used and one should also have a Teflon-coated stirring bar chaser which allows one to retrieve stirring bars from solutions. This is an invaluable item for general lab work.

- 1000ml and 5000ml Pyrex graduated beakers. The 1000ml beaker should be thick-walled Pyrex as it needs to be slightly more heavy-duty. Do not use ordinary glass or Mason jars as we will be heating it directly on the hotplate.

- A jewelers oven. These ovens are available from jeweler's supply companies. Look in the yellow pages. They typically have a meter which monitors the temperature from 0-1200°C and a rotary adjustment knob which controls the temperature. The inside is lined with firebrick, as is the door, and there is a small vent hole at the top. Buy one with an interior width and depth of at least 9". They cost about $400 and can be purchased by anyone. An extra firebrick may be required to center the oxidation vessel. Firebricks can be found at most fireplace/woodstove stores.

- One 1000ml round-bottom flask.

- An 8"x8"x2" Corningware casserole dish with Pyrex top. This item is important because it is the vessel we will use to perform the oxidation procedure, which takes place at 520°C. Ordinary glass will shatter at these temperatures, and Pyrex does not hold up much better. Corningware will stand up to these temperatures and heating cycles, but just barely. The Pyrex tops that come with the casserole dish often crack or break after only one or two reactions, so extra tops should be purchased. A ceramic or clay vessel would be better, but are difficult to find in the correct size. The Corningware dishes are cheap, disposable, and can be purchased anywhere.

- A 4" diameter Buchner.

- A 1000ml filter flask.

- Whatman Qualitative 5 filter papers. Purchase the size that fits your largest Buchner and cut to fit for the smaller Buchners. These filters will catch the finest particles of catalyst. Equivalent filter paper is made by other manufacturers.

- A mortar-and-pestle set, medium sized. These can be found at many organic food and food-supplement stores, as well as in children's science shops.

2.4 Chemicals

The following chemicals will be used:

Laboratory grade 37% hydrochloric acid. One can try hardware store muriatic acid if it is 30% or better. It is unknown what the impurities in the cheap hardware-store stuff may do to the catalyst, but many times the only difference between laboratory grade chemicals and commercial grade stuff is the fact that the laboratory grade chemicals have been tested to make sure there's nothing strange in it. It may have come out of the same tanker car, but it was tested.

One will need 200ml of 70% nitric acid in order to make aqua regia. Jewelers can buy this in very small quantities for making aqua regia, which is required to dissolve metals like platinum and rhodium for alloying or plating. Otherwise, one can whip up a batch fairly easily. See Section 6.0 for instructions.

About 3 kg of sodium or potassium nitrate. This is our oxidizer, and it is used at a 10:1 weight ratio with ammonium chloroplatinate (which we will make). It is also used to manufacture 70% nitric acid. Sodium nitrate is preferred, but only because this writer has used it extensively. Use the powdered form as it requires less grinding and seems to work better than the beaded form often found in university labs.

About 3 kg of ammonium chloride will be used. This common salt is used for metal preparation and making chilling solutions. It should not be difficult to find. Try the drugstore or pharmacy.

2.5 Dissolution of Platinum in Aqua Regia

The first step is to dissolve the platinum, either in coin form or as spent catalyst, in aqua regia to make chloroplatinic acid. This is not as easy as may first appear. Platinum coins are especially difficult to dissolve. Left on it's own, it could take months for the platinum to completely dissolve. Heating to just below the boiling point of the acid will increase the activity of the acid many times and will let the chemist dissolve his platinum coins in 3-4 days. Spent catalyst may also be recycled, and will dissolve much more quickly than coins. This procedure must be performed inside a properly functioning fume cabinet or the fumes will kill you. See the appendix for construction details.

Place a 1000ml Pyrex beaker on the stirring hotplate. Place a 2" Teflon-coated stirbar with a center ridge inside the beaker. If one is using fresh 1oz platinum coins, gently place two of them (64g) in the beaker. There should be room for the stirbar to turn without touching the coins. Two coins is the very most one should attempt to dissolve in 800ml of aqua regia as additional platinum will not dissolve and react but will remain as unreacted particles in suspension, screwing up subsequent procedures. (If one is recycling spent platinum dioxide catalyst, wait until after the aqua regia is made and stirring, but not heating, is begun before adding the spent catalyst in small portions.) Add 200ml of 70% nitric acid. Add 600ml of laboratory grade 37% hydrochloric acid. Once the platinum and aqua regia are inside the beaker, fill a 1000ml round-bottom flask half full of cold tap water, dry the outside with a paper towel, and carefully place it on top of the beaker. Make sure there is an air-gap at the pouring lip of the beaker so no pressure builds up. This is our makeshift condenser, designed to condense and recycle the aqua regia while the platinum dissolves. Without the condenser, the aqua regia will quickly boil off without dissolving much platinum. Do not fill the 1000ml flask to more than 1/3 or ½ full or it will become top-heavy and tip over from the vibration. Begin heating while stirring, slowly raising the temperature over several hours until the first signs of boiling begin. On my stirring hotplate, an 800watt unit, the heat setting is 3.5-3.75. The solution will turn orange, and then a very deep ruby red. Do not leave the reaction unattended for more than a few minutes, and turn it off at night. When recycling spent catalyst, a small amount of contaminant may appear on the surface. Let the beaker cool until it can be handled and then filter the liquid through your 4" Buchner using filter paper, holding the coins in place with the Teflon-coated stirbar chaser. Do not use any metal, as it can contaminate the batch. A more porous grade of filter paper may be used. Pour the filtrate back into the beaker with the coins and continue the heating and stirring. It should take 3-4 days to dissolve two coins. The variables affecting dissolution speed are surface area, acid temperature, and stirring effectiveness.

One needs to mix up a saturated solution of ammonium chloride in distilled water. Pour 3000ml of distilled water into a 5000ml beaker (or a 1gal pickle jar) along with a 3" stirring bar. Place on a stirplate if available, otherwise stir using a clean spatula from the kitchen. With stirring, slowly add ammonium chloride to the water until it will not dissolve any more. Continue stirring occasionally until the solution comes up to room temperature once again, then add more ammonium chloride until no more will dissolve. Repeat one more time. When finished, the chemist should have a room temperature solution with a little undissolved ammonium chloride at the bottom.

Once the platinum is completely dissolved, remove the condenser flask and allow the remaining acid to boil off until it is all gone and there remains in the bottom of the beaker a grayish-red-black layer of ugly metallic stuff. This is chloroplatinic acid. Be aware that the fumes created when boiling off the acid will create large, very visible clouds of acid-laced fog if exhausted into cool, still air. In addition, all nearby plant life will turn brown and quickly die. If performed while a stiff breeze is blowing, this hazard is eliminated. Let the beaker cool down, add 500ml of 37% hydrochloric acid, let it react with the chloroplatinic acid, then boil off the acid almost to dryness. Do this three times to remove any trace of nitric acid, boiling off the acid to dryness on the third boil. Once cool, add small portions of ammonium chloride solution and work it with the end of a stirbar chaser. Continue adding ammonium chloride solution until all of the chloroplatinic acid has reacted and there are no solid chunks left. Decant into another clean beaker or jar as the beaker fills. A bright yellow suspension will form as the chloroplatinic acid reacts with the ammonium ion to make ammonium chloroplatinate. Do not get in a hurry. It can take over an hour for the chloroplatinic acid to completely react. Black particles or other discoloration is a sign of incomplete dissolution of the platinum. Remove the water by vacuum filtering through the 4" Buchner with Qualitative 5 filter paper using a water aspirator or vacuum pump. This also may take several hours. Remove the pasty ammonium chloroplatinate cake and break it up as finely as possible using a clean razor knife in a glass bowl or plate. It will be difficult to handle and a little sticky. At this point one must improvise a little. I use a vacuum oven purchased at a mining equipment sale (mines do a lot of inorganic chemistry) to gently vacuum dry the ammonium chloroplatinate overnight at low heat. Those without vacuum ovens should use an infrared lamp placed near the plate and be patient. Do not overheat, as ammonium chloroplatinate will decompose. Look for any brown or black discoloration as a sign of excess heat. Break up into smaller chunks as the paste dries. Dried ammonium chloroplatinate is hard, granular, and dark yellow in color.

Ammonium chloroplatinate is a convenient form in which to store catalyst, as platinum dioxide catalyst can be extremely pyrophorric (this stuff explodes!). Store in a cool, dry place and oxidize it as the need for fresh catalyst arises. If one started with 64g of platinum coins (Pt, 195g/mole, 0.328mole), one should end up with slightly less than 0.328 mole of ammonium chloroplatinate ((NH4)2PtCl6, 443.9g/mole), or about 140g. This is enough to make about 50g of useful catalyst, which translates to 150-300 moles worth of reactions, or about 40-80lb of very pure methamphetamine, depending upon how many times one is able to reuse the catalyst.

2.6 Oxidation of Ammonium Chloroplatinate to Platinum Dioxide

This is where the rubber meets the road in this procedure. We must mix our ammonium chloroplatinate with sodium nitrate, our oxidizer, and burn it. In the old days, when Adams invented this catalyst, they used a copper-alloy block with a crucible and a hole drilled for the insertion of a thermometer to measure the temperature. Our procedure isn't much better, but if Adams could do it with crude equipment, perhaps we can optimistically expect to do as well. At this point, your humble writer must point out that he has never made a batch of catalyst that did not work, even though experiments were performed over the temperature range of 480-530°C. This is not due to some extraordinary intelligence or experience. It is because this is easy to do. The accompanying poor quality picture shows new brown catalyst on the left and spent black catalyst on the right.

The ammonium chloroplatinate must come into "intimate contact" with the oxidizer, according to Adams. To accomplish this, place 50g of sodium nitrate in a layer at the bottom of your mortar-and-pestle set. Add 5g of ammonium chloroplatinate chunks to the bed and grind until all chunks are thoroughly blended into a homogenous yellow powder. Be thorough here, as it will pay off in catalyst yield. Shake the mixture into the 8"x8" Corningware casserole dish. Do this five times for a total of 25g of ammonium chloroplatinate and 250g of sodium nitrate. Do not attempt to do more than this-it makes a terrible mess inside the oven. A safer amount is 20g, but 25g batches will work reliably if the oven is controlled properly.

Spread the yellow powder evenly across the bottom of the casserole dish, replace the Pyrex cover, and place the dish into the jeweler's oven. The idea here is to place the dish so the temperature on the front meter accurately reflects the temperature inside the vessel. If one has a large oven with the temperature sensor in the center, adjust the position of the dish with varying thicknesses of firebrick. If the heating element runs directly beneath the dish, spot heating should be avoided by placing a thin firebrick across the bottom. We are operating close to the temperature limits of the vessel material, so a little diligence is required. The oven should be placed inside the fume cabinet where the noxious fumes produced can be exhausted, preferably into a stiff wind at night. Secure the latch on the oven. On my oven, the temperature control is graduated from 1 to 10. I set the control on 3.75, having learned the hard way that too-rapid heating will shatter the casserole dish. The temperature will slowly climb over a period of 2.5-3.0 hours to 520°C, at which point the heating element is turned off and the chemist leaves the oven to cool down overnight. He does not open the door of the oven, even a crack, until the temperature is all the way down. Failure to exercise patience will be swiftly punished with a shattered dish and a nasty mess. One should watch the oven carefully, noting that the heating element cycles on and off and correlating that with changes on the temperature indicator. This will improve one's precision in controlling the oven temperature in the event one should desire to experiment, which this writer encourages. A plume of brown fumes should begin to rise from the exhaust hole at the top as the oxidation begins. This usually occurs starting at 380-400°C and can continue all the way up to about 500°C, but not always, and not predictably. This writer has discovered empirically that the temperature range over which catalyst can be successfully produced is 490-520°C, with the best catalyst being made at 510°C. As the meters used on these ovens are the inexpensive current-shunt type, they are accurate to about ±2%, which is about 10°C either way, so there can be as much as 20°C variance in the temperature indicator from unit to unit. In addition, the temperature sensors used have tolerances that can stack up in the wrong direction. The point here is that your oven may read differently than mine, so one should be observant and adjust the setting based upon the results of the previous oxidation. If the stuff turned out burnt, lower the temperature.

Open the door-latch of the cold oven and remove the casserole dish. Pry the top off gently with a screwdriver, as it will be fused with white sodium nitrate residue. Inside will be a layer of hardened sodium nitrate mixed with and covering a layer of brown-black powder which will have spattered and coated the inside surface. Pour some distilled water into the top and gently work it with a plastic spoon to dissolve the sodium nitrate and free up the platinum dioxide particles. Carefully pour the resulting liquid into the clean 5000ml beaker. Repeat to recover the last traces of catalyst stuck to the cover. Pour distilled water into the casserole dish until the bottom layer is covered and break up the hard layer as gently as possible with a clean screwdriver. Work the chunks until they are broken up into pieces small enough to handle. Using surgical gloves, very carefully place the larger pieces into the 5000ml beaker, rinsing one's fingers with distilled water into the beaker. Once the large pieces have been removed, add water and work the dish until one is satisfied as much catalyst as possible has been recovered. Add distilled water to the large beaker until it is almost full and stir until all of the sodium nitrate has dissolved and one is left with a dark brown suspension that gradually settles to the bottom of the beaker. Let it settle overnight then carefully decant the water without disturbing the catalyst layer at the bottom. Decant as much water as possible without losing catalyst, then refill with more distilled water, stir thoroughly for 15 minutes, then let it settle overnight once again. Do this four times to insure all the nitrate is dissolved and removed. Successive washings will result in the catalyst taking longer and longer to settle out, until, on the fourth one, the catalyst may become colloidal and not settle out completely. Using the Whatman Qualitative 5 filter paper and a clean Buchner, filter the catalyst suspension, washing the beaker with distilled water to catch the last grains. One should now have a layer of wet, medium-to-dark brown catalyst in the Buchner. Gently work the small cake loose onto a small glass or porcelain plate and spread it out using a fine-tipped razor-knife. Let it dry in a warm, but not hot, place. Once dry, carefully scrape the loose powder into a clean spice bottle, which makes an ideal container. Do not let it fall freely through the air more than a few inches as this can, and will, result in a display of pyrotechnics as your catalyst explodes while you watch. This is especially true when the temperature drops below freezing or one is in a very dry area. One should now have about 11g of platinum dioxide (PtO2, 227.09g/mole, 0.048mole) for a yield of about 85%.

Repeat the above three steps until all the ammonium chloroplatinate is used. One should have 50-60g of catalyst in the form of a very finely divided dry brown powder. Store in a cool, dry place and avoid static discharges. There is some debate about whether or not this catalyst decreases in activity level over periods of time exceeding 6-12 months. It has been this writer's experience that the catalyst itself maintains it's activity level as long as it has not been pre- reduced or otherwise exposed to concentrated hydrogen. There are many other factors that can easily cause a decrease in yield or an increase in reduction time that can be misinterpreted as a change in catalyst activity. This catalyst is very sensitive to the level of self-oxidation or residual acids in the P2P. In addition, slight variations in agitation effectiveness can appear to be catalyst-related.

3.0 The Hatch-Feinstein Reduction

Application of Platinum Dioxide Catalyst to the Reductive Amination of 1-phenyl-2-propanone (P2P). In this section the chemist pre-reduces the catalyst and reductively aminates both test and production quantities of P2P.

3.1 Discussion

The prudent chemist always runs a small test batch before using fresh chemical components, in this case either P2P, methylamine, or catalyst. In addition, there is a requirement for a pre-reduction vessel for the catalyst. This writer will tell you flat-out that the literature on the subject of pre-reduction is wrong. First of all, this catalyst must be pre-reduced in distilled water, not ethanol. Dropping this catalyst into alcohol is an excellent way to start a fire. Although this catalyst is gradually reduced down to platinum during it's exposure to hydrogen, only in the very poorest of catalyst does this occur in less than three uses. In every case, however, the catalyst required pre-reduction. The amount of pre-reduction required varies from batch to batch and the chemist must learn to tell from observation when the catalyst is ready for use.

3.2 Test-vessel construction

One must construct some simple equipment in order to run test-batches and pre-reduce catalyst in appropriate amounts.

Fortunately, the equipment can be fairly simple because we are only required to provide agitation and low pressurization. Eliminating the requirement for heating simplifies things immensely. As one can observe in the accompanying picture, this writer constructed a vessel out of an old 3000ml reagent flask. It has the advantages of being narrow, thick-walled, and having a flat top. The bottom plate is 3/16" aluminum plate , the connecting rods are 3/16" all-thread found at the auto parts store. The top plate is ¼" aluminum plate recovered from the scrapyard. The gauge is a -30"Hg to +30"Hg, liquid-filled, combination vacuum/pressure unit. They cost about $30 at industrial equipment supply stores. The pipe is common ¼" NPT wrapped in Teflon tape. Everything is connected together with a brass 4-way fuel block with ¼" NPT thread available at the auto parts store. The valves on either end are common gas valves found at welding equipment suppliers. One can use oxyacetylene valves as they are ¼" NPT on one side and gas thread on the other. This allows one to make a direct connection between the hydrogen tank regulator and the vessel using the red hose of an oxyacetylene torch set. The same valve on the other end is fitted with a 3/8" nipple for pulling a vacuum. The rubber gasket used to seal the aluminum top-plate and the bottle-top is cut from 1/8 " rubber gasket material found in the plumbing department of the hardware store. One must adapt this design to the equipment available. A 2000ml filter-flask can be made into an excellent vessel by sealing off the side-nipple (hose, screw, and clamps) and using a modified rubber stopper on the top opening.

A smaller glass vessel is also required for pre-reducing 1g batches of catalyst. The vessel should be about 500ml or less in volume. This is necessary because of the physical limitations of attempting to pre-reduce tiny volumes of catalyst in a large vessel, especially considering the fact that one must determine visually the pre- reduction state of the catalyst. The bottom plate must be made of aluminum so a magnetic stirring bar can be used for agitation. The unit is placed on a stir-plate, the air evacuated, then charged with hydrogen and agitated until the catalyst is pre-reduced.

3.3 Pre-reduction of platinum dioxide

Much of the existing literature concerning Adam's catalyst describes pre-reducing the catalyst in ethanol and/or allowing the catalyst to pre-reduce in situ. My experience indicates both techniques are wrong. Attempting to pre-reduce this catalyst in ethanol resulted in several small fires and explosions. Attempting to pre-reduce the catalyst in situ worked on only one batch of catalyst, which was the poorest catalyst made.

The procedure that works reliably, every time, is to pre-reduce in distilled water. The pre-reduction process involves exposing the catalyst to hydrogen gas under pressure, resulting in a change in both color and character of the platinum dioxide. Carefully weigh out 1g of catalyst on a triple-beam scale. Place the catalyst into a small (50ml) beaker and add 10ml of distilled water. Carefully pour the resulting slurry into the small pre-reduction vessel through a small funnel, chasing the slurry into the vessel with an additional 10ml of distilled water. Place a small Teflon-coated stirbar into the vessel and seal by carefully cinching down on the retaining nuts on the top plate. Make sure the hydrogen gas valve is closed and the vacuum valve with the nipple is open. Attach the 3/8" hose from your vacuum aspirator and pull a vacuum in the vessel to about 25"Hg. Close the vacuum valve and watch the gauge for a minute. If it doesn't move, your vessel is holding a vacuum. Now open the hydrogen tank valve and increase the pressure at the second stage of the regulator to 30psi maximum. Open the hydrogen inlet valve on the catalyst vessel, pressurizing to 30psi. Close the vessel hydrogen valve and watch the gauge for a drop in pressure. If there is a leak, one can find it rapidly using dishwashing soap mixed with water in a squirt bottle. Once the vessel is pressurized with no leaks, begin stirring as rapidly as possible. The catalyst will be thrown against the interior wall of the vessel as it is splashed around. Adjust the position of the vessel on the stir-plate to maximize the splash. The catalyst will begin to turn from brown to black in color. After an additional amount of time, small particles of catalyst will begin "sticking" to the vessel wall, soon forming a "ring" of tiny black flakes or particles. Once most of the catalyst is in the "flake" form and all of the catalyst has turned from brown to black, it is pre-reduced.

Over-reduction can easily take place, and as this drastically decreases the activity level of the catalyst and reduces it's useful life, this is to be avoided. The catalyst will pre-reduce more quickly during warm weather, but the pre- reduction time varies more from batch-to-batch than with any other factor. One should use 20ml of distilled water for every gram of catalyst. Using less increases the chance of over-reduction while excessive water requires the addition of more ethanol to the reaction solution to maintain homogeneity, thus decreasing catalyst density and increasing reduction time. Typical pre-reduction times are 10-25 minutes.

Once the chemist is satisfied that his catalyst is pre-reduced, he makes sure all hydrogen valves are closed and then slowly opens the vacuum valve to release the excess hydrogen. One should keep in mind that hydrogen reacts with oxygen to make water, with an accompanying release of energy--one should be careful when opening hydrogen gas valves into an atmosphere containing oxygen. Once the pressurized hydrogen has been released, it is time to move the catalyst to the reaction vessel. The best way to do this is to partly fill the pre-reduction vessel with 95% ethanol, then pour the slurry into the reaction vessel using a funnel. Repeat until all the catalyst is picked up. The chemist is now ready to make his product.

3.4 Primary reaction vessel construction

The design of one's primary reduction vessel should be tailored to the batch sizes and the quality of agitation one desires.

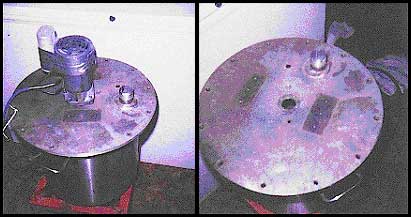

This writer constructed an adequate reaction vessel using a section of 8" stainless-steel pipe found at the scrapyard along with some stainless plate and threaded fittings (see pix).

In addition, a rocker was constructed using common steel plate, a gearmotor, and some pulleys purchased at the hardware store. A cyclic rate of 100 RPM was chosen arbitrarily (I guessed) and provision made in the design to allow one to swap pulleys and change the cyclic rate. A throw(rock) of 3" was determined to be the most one could expect given the motor torque (32 in-lb) and the weight of the vessel when fully charged (about 10lb). The motor used is a gearmotor from a scrapped copier which one can readily find at electronics surplus houses along with the required capacitor for less than $100. A new gearmotor of the proper size will cost 4-5 times that much. These are very useful, reliable motors that this writer uses for many purposes. Try to find ones with a machined face so they can be quickly mounted to brackets, etc. The resulting rocker provides a rocking rate of 110 rpm and completes a reaction in six hours.

Our stainless reaction vessel has an internal capacity of 7000ml, of which only 3500ml is used when fully charged with a 6.5-mole batch. This batch size was selected because of equipment and time restrictions-one can squeeze a 3500ml reaction into a 5000ml round-bottom flask for solvent stripping and the resulting 900g of methamphetamine base divides conveniently into two 450g portions for crystallization, which will take about 4 hours to perform. This is a full day's work for one person, resulting in 2lb of product.

An improved reaction vessel can be constructed using a paint shaker for optimum surface-area creation. These units hold one-gallon paint cans, which, when full of paint, weigh much more than our reaction solution, eliminating concerns about exceeding any weight limitations on the machine. One may have a reaction vessel made which will fit into the machine clamps and have the following properties; 1) it will be constructed of thin-wall 316 stainless steel and stand up to 100psi when sealed and will not collapse when a 29"Hg vacuum is pulled (this means a round body and thick ends), 2) it will have a threaded opening about 1.5-2" at one end to pour stuff into, and, 3) it will have an internal volume of at least 4000ml. The best way to do this is to have a machine shop roll a sheet of 0.065in 316 stainless sheet into a cylinder and then weld the seam. End pieces are cut from 0.375in 316 stainless and tig-welded to our thin-wall pipe. Prior to welding to the cylinder body, one end-piece is drilled out and a 1.5" stainless coupling with NPT thread is welded on. The unit is then pressure tested to 100psi and vacuum tested to 29"Hg. The threaded coupling is fitted with a bushing that allows a gas fitting to be attached. Use Teflon tape to seal all threads, including the gas fittings. Leaks must be avoided. This one gallon (4liters) vessel can hold 3500ml of reactants with ease, resulting in the same product volumes as one obtains using the rocker. The improvement comes in the vigorous agitation provided by the paint shaker; by making sure that the hydrogen inlet hose rises straight up from the vessel to avoid losing reactants into the hose, the reaction will reach completion in 3 hours instead of 6 using the same catalyst density of 1g/mole. Using very little ingenuity, one can obtain a paint shaker that holds 5-gallon pails and construct a reaction vessel which will do 30-mole batches in a few hours, resulting in about 10lb of finished product after processing. The batch can be processed in 22- liter glassware by reducing the ethanol volume slightly, but will require a high-volume vacuum source to do the distillation. The main drawback to doing huge batches is that if one makes a mistake, he has just blown a whole lot of very valuable precursor material. The prudent chemist does not bite off more than he can chew up in one day.

3.5 Reductive amination of P2P using Adam's catalyst

While the catalyst is pre-reducing, the chemist must prepare a Schiff's base from his P2P and methylamine solution.

For a 1-mole test batch using 1g of catalyst, one pours 150ml of 37-40% methylamine solution into a 1000ml beaker along with a stirring bar. With stirring, 134g(1mole) of 1-phenyl-2-propanone is added. This should be done inside the fume cabinet to avoid the strong smell of decaying fish that accompanies methylamine solutions. Cover the beaker with a clean shop rag while stirring continues. In a separate container, measure out 250ml of 95% ethanol. 95% ethanol can be purchased as very strong vodka under various brand names (Everclear?), but my favorite source of ethanol is found in almost every supermarket and drugstore. It is called Rubbing Alcohol Compound. This is very different from Rubbing Alcohol, which is the trade name for isopropyl alcohol. Rubbing Alcohol Compound has replaced isopropyl alcohol on grocery shelves because the ethanol subsidies provided by the feds allow the use of cheap subsidized ethanol instead of the more expensive isopropyl alcohol. Rubbing Alcohol Compound is 93% ethanol along with 2% ethyl acetate or some other denaturant that makes you sick if you drink it. Fortunately, the denaturants do not affect our reaction and now one has an inexpensive source of reaction solvent upon which no liquor taxes are paid. This writer has tried every brand available in my area and they all worked just fine. In a serious pinch, the chemist can use methanol instead of ethanol, although the reaction will take three times as long to complete with a similar yield. When the catalyst is ready, slowly add, with stirring, enough ethanol to clarify the solution. This should take about 125ml for a 1-mole batch, leaving 125ml to use in retrieving the catalyst from the pre-reduction vessel. Add the clarified P2P/methylamine solution to the reaction vessel and rinse the beaker with a dash of ethanol, adding the rinse to the reaction. One should now have a reaction vessel containing 20ml of water, 250ml of ethanol, 150ml of methylamine solution, and 135ml of P2P for a total volume of about 550ml. Keep this number in mind when designing a larger reaction vessel. Seal the reaction vessel, pull a 25" vacuum using a water aspirator, pressurize to 5psi with hydrogen, pull another 25" vacuum, and then pressurize to 25-30psi with hydrogen. Do not pull a vacuum harder than 25"Hg or the methylamine will boil off. Check for leaks. If no leaks are found, begin the agitation by turning up the stirring to full blast.

Agitation is important because it creates surface area. For the reaction to take place, the catalyst, a molecule of our Schiff's base, and an atom of hydrogen must come into contact simultaneously. Since we are dealing with solid, liquid, and gas phase materials, this can be difficult. The splash, or agitation, is the single most important physical variable affecting this reaction. The more surface area one can create, the better the chances are of our three reactants meeting and making meth.

At this point, one would like to know if the reaction is proceeding correctly and at what rate so one knows when the reaction is done. Our pressure/vacuum gauge along with our gas valve will provide this information. Once the reaction vessel is pressurized to 30psi, close the hydrogen valve and begin the agitation; the reading on the pressure gauge should drop over a short period of time. In my test vessel, a pressure drop of 10psi occurs in 11-16 minutes, depending upon how good the agitation is. Yours may be different. Once the pressure has dropped 10psi, open the hydrogen valve again and re-pressurize to 30psi. By precisely recording the amount of time it takes to cause a pressure drop of 10psi, the chemist can tell whether the reaction is proceeding or stopped for some reason, how well (quickly) the reaction is going, and when it is done. This can be vital information if something is going wrong. Typically, a 1-mole reaction in this writer's test vessel will use a 10psi gulp of hydrogen every 13 minutes for 10 gulps, and then begin to slow down as the reaction begins to have difficulty finding unused reactants. A total of 18 10psi gulps of hydrogen are required to complete a 1-mole batch in my test vessel. The last hydrogen gulp takes well over an hour to finish, with a total elapsed time of about 4-6 hours to complete the reaction. Using a known volume and pressure, one can calculate how many pressure drops it will take to use up a mole of hydrogen.

With the reaction done, the chemist pours the reaction solution into a 1000ml beaker and rinses the vessel out with a little ethanol, adding the rinse to the beaker. One must now remove the catalyst before processing. This is accomplished by using a small(2") Buchner along with Qualitative 5 filter paper and filtering into a 1000ml filter flask. Capture the remaining particles of catalyst in the beaker with ethanol. At this point, the chemist must be on his toes because the catalyst in the Buchner will catch the alcohol on fire if it is not quickly quenched. This is done by pouring a layer of distilled water over the catalyst and allowing the vacuum suction to pull it through, taking the alcohol with it.

One must always keep in mind that this catalyst is very pyrophoric, meaning it will burst into flames or explode at the slightest provocation. Things one should never do with this catalyst at any time, but especially once it has been pre- reduced, are; 1) allow it to fall freely through the air for more than a few inches, 2) allow it to come into intimate contact with flammable solvents such as ethanol, methanol, etc., and, 3) expose it to open flame. We have forced hydrogen atoms into the lattice structure of the platinum dioxide crystals, and that hydrogen reacts with oxygen both in the air and the platinum dioxide (reducing it over time to platinum), and this reaction creates heat which will catch things on fire. A static charge of sufficient intensity, such as that picked up when falling freely through dry air, will cause the catalyst to explode, although not with an intensity that will damage anything but one's dignity.

Now that the catalyst is removed, pour the filtrate into a 1000ml round-bottom (RB) flask and distill the ethanol and methylamine off until the temperature reaches 90-92°C. Turn off the heat, attach an empty receiving vessel, then slowly apply a vacuum by gradually closing the bleeder valve on the water-aspirator system. When the temperature has dropped and the vacuum is down to 28-29"Hg, turn on the heat again and vacuum distill off the residual water until the condenser is clear, which will occur between 50-60°C. Remove the heat and allow the remaining meth base to cool a little. With fresh boiling stones and a clean receiver that has been weighed, reapply the vacuum and distill the meth base over a 10°C range. Adjust the vacuum using the bleeder valve so that the meth base distills over at 95-105°C. Meth base is a clear, colorless liquid. If it is anything but clear and colorless, it contains contaminants. The accompanying picture shows the result of a 6.5 mole batch, which produces about 900g of meth base.

A one-mole batch of P2P with 100% conversion would result in 149g (one mole) of methamphetamine base, but the typical yield is 90-93%, resulting in 134-140g of base. Meth base will quickly react with carbon dioxide in the air to form the carbonate, so it is advisable to crystallize the base as soon as possible. Crystallization is performed by adding 450g(3 moles) of meth base to a 1000ml Pyrex beaker and placing the beaker on a stirring hotplate. Carefully drop in a Teflon- coated stirring bar and begin stirring. One now adds 37% hydrochloric acid in 15ml portions. A graduated 15ml test-tube makes an ideal dispenser. A great deal of heat is generated as the acid reacts with the meth base and will result in boiling if added too quickly. Add 15ml of acid at intervals of 1 minute until 19 portions (285ml) have been added, then add acid in smaller portions and watch the color carefully. If the meth base was clean to begin with, it will turn light pink when the pH reaches 3-4. Test with pH strips(Colorphast 0-14 strips) or a meter. Stop adding acid when the pH reaches 3.

Now we must boil off the water contained in the acid, as water solvates meth very efficiently. Turn the heat on the hotplate to 4.5 while stirring continues and place a thermometer that reaches 150°C into the beaker on the bottom. Over the next 1.5 hours, the temperature will climb to 110°C where boiling begins, then gradually rise as the water is boiled off. When the temperature reaches 130°C, turn off the heat and remove the thermometer. Using a dishtowel, grip the beaker with both hands and quickly pour it into a 5000ml plastic bucket containing 4.5 liters of acetone which has been frozen for 2 weeks. Retrieve the stir-bar with a chaser, replace the lid and return to the deep freeze for 1 week to allow complete crystallization. Clean, freshly distilled acetone will retain about ¼ lb of product the first time it is used, which is why one should recycle one's acetone. Alternatively, one can pour the hot methamphetamine hydrochloride into a 5-gal plastic bucket containing 4.5-gal of acetone that has been frozen for about a month (it takes a long time to pull the heat out of a large mass). The meth will crystallize the instant it hits the frozen acetone, although about 25% will remain in the acetone and must be frozen to crystallize.

Paradoxically, dirty meth crystallizes better than pure meth because the crystals quickly grow around a particle of impurity, forming nice large, hard crystals. The meth crystals are filtered out using a large Buchner, two 4000ml filter flasks, and a high-volume vacuum aspirator. An 18cm porcelain Buchner will hold a little over 1 lb of filtered product. Do not use Qualitative 5 filter paper for this filtration. This writer has found that the filters used in milk processing equipment are ideal for meth harvesting. A lot of money has been spent by the dairy industry over the years figuring out how to quickly filter solids out of mixed-phase solutions. These filters will allow liquids, both water and oils, to pass freely while trapping the finest solids, making them ideal for rapid filtering. The problem with the fine paper filters is that oil-water mixtures plug them up very quickly. Milk filters do not have this problem and they are easy to find, cheap, and suspicionless. One will need to cut-to-fit, but this is a small inconvenience. A suitable high-volume filtering setup can be easily made using 5 and 20-liter buckets, a round plastic plate, and some glue. This writer was fortunate enough to discover a large Buchner being used as a planter by a nice lady in my neighborhood. Happily paying the lady for a replacement, the retrieved treasure holds over 2lb of product and makes the chemist's life much easier. The point is that one can find useful equipment almost anywhere. Pure meth is more difficult to crystallize, and results in a light, flaky white product with a mild scent of marzipan (actually benzaldehyde). Empty the product into a large cake tray and let the acetone evaporate in the fume cabinet for a day or two, separating it as it dries.

This product may be cut with powdered niacinamide (vitamin B3) at a 4:1 ratio (20% cut) to make a product that burns clean and is water-soluble. Do not use vitamin B-3 tablets which contain insoluble buffers that burn dirty.

4.0 Manufacture of 1-phenyl-2-propanone

The manufacture of P2P utilizing benzaldehyde and nitroethane is described. We will be using a two-stage procedure involving the Cope modification of the Knoevengel reaction and an iron-acid reduction procedure. The chemistry of this procedure has been described by Uncle Fester in his Secrets of Methamphetamine Manufacture, 3rd ed., thus we will concentrate on scaling up the reaction to the point where it can be used for very high-volume manufacture.

4.1 Equipment

The following equipment will be required.

- A rigid-base heating mantle with dual-element controls that holds a 22-liter round-bottom triple-neck.

- A 22-liter, 3-neck, round-bottom reaction flask

- A 45/50 to 24/40 glass fitting adapter

- A Dean-Stark trap

- Two 30cm West condensers

- Several 5-liter and 20-liter plastic buckets

- Fabricated equipment described below

4.2 Chemicals

- Benzaldehyde

- This is our basic starting material. One mole of benzaldehyde weighs close to 100g and has a density close to 1g/ml. Since we will be performing 25-mole reactions, we will use 2500ml of benzaldehyde per reaction. All other reactant quantities are derived from this figure. Purchase the chlorine-free type if available, but the standard product works fine. Store in a cool, dark place. Benzaldehyde will auto-oxidize somewhat over time, but is nothing to get excited about-this stuff will keep. The oxidation product is benzoic acid, which takes the form of well-defined white crystals at the bottom of the container. Try not to get any of the crystals into the reaction. They won't kill it, but will reduce the yield. Benzaldehyde has a strong odor of marzipan. It can be vacuum-distilled in order to clean it up, but has a tendency to bump vigorously at vacuum levels that are high. Benzaldehyde has been relatively easy to obtain until recently.

- Nitroethane (EtNO2)

- This is the material we will react with the benzaldehyde molecule in order to produce 1-phenyl-2-nitropropene. It supplies the carbon sidechain and nitro group that are required to produce the nitrostyrene. EtNO2 is a clear, pleasant- smelling liquid which boils at 114-115°C, has a molecular weight of 75.07g/mol, and a relative density of 1.05. It distills nicely without vacuum. Since we will be providing a 5% excess of nitroethane in order to ensure there are enough molecules available to combine with the benzaldehyde, we will require 26.25 moles of nitroethane((26.25mol x 75.07g/mol)/1.05), or 1,875ml for each batch. One can use the industrial grade nitroethane, but it must be washed and distilled before using. To clean it up, pour about 3000ml of nitroethane into a 4000ml separatory funnel, add 500ml of distilled water, shake thoroughly, allow the water to separate to the top over a 24-hour period, then drain the nitroethane and distill it, discarding anything that comes over below 110°C. It is important that the nitroethane be clean. One should be aware that nitroethane has become a high-suspicion product because it sounds much like nitromethane, which is the booster that was added to the Oklahoma City bomb. Do not confuse the two.

- n-butylamine (n-BuNH2)

- This is our catalyst. Do not use "sec-" or "tert-" butylamine, as they will not work(the "n-" means "straight- chain"). In addition, because n-butylamine is a very strong base which reacts with carbon-dioxide in the air and almost anything else it contacts, one must insure that the catalyst is clean. The best way to do this is to distill it. Do this inside a fume cabinet as this stuff is very ugly. Don't breathe it and don't touch it. One must wrap the stopper or cork on the distillation rig in Teflon tape to prevent it from being eaten. The amount of catalyst used in our 25-mole reaction is nominally 20ml/mole, but experience has shown that the actual amount is closer to 23ml/mole, so one should purchase an amount that will provide a volume of 25ml/mole of benzaldehyde. The actual amount must be determined by observation and adjusted accordingly. The use of catalyst that is not pure will result in a drastic reduction in yield.

- Ferric Chloride (FeCl3)

- This innocuous chemical is used in our reduction reaction in small quantities as a "steerer", which modifies the reaction equilibrium in the direction we desire. A few kilos of this can do a lot of reactions.

- Catalytic Iron Powder (Fe)

- Used in the reduction procedure, the iron reacts with hydrochloric acid to produce hydrogen gas. Due to the requirement for good dispersion during the reduction, the use of a fine mesh powder is necessary, either 80 or 100 mesh. A coarser 60 mesh powder can be used, but may result in some problems if the stirring system is inadequate. The reaction requires 200g of iron powder for every mole of 1-phenyl-2-nitropropene that is reduced. Since we will be performing 20- mole reductions, each reduction will require 4000g of iron.

- Muriatic acid (HCl)

- This is simply dilute hydrochloric acid, usually about 28-32% as compared with 37% HCl. It works just fine, however, and has the advantage of being available at almost any hardware store. A volume of 750ml of 37% HCl is required for every mole of 1-phenyl-2-nitropropene that is reduced, resulting in 15 liters of acid required for every 20-mole reduction. It has been this writer's experience that the more dilute muriatic acid performs just as well as the stronger stuff in the same volume.

- Methanol (MeOH)

- This is used as a solvent when processing the yellow nitropropene crystals. Purchase methanol which has not been diluted with water-some of it is only 60% methanol. Keep it in the deep freeze.

- Toluene

- This is our solvent for the Knoevengel reaction. It is available in every paint store, although many companies are relabeling their solvents with house names so the narcs don't hassle them. Use the "UN" number, which must be on every container, to identify the product. Or just ask. Most paint store employees don't know the difference between toluene and neoprene and will happily tell you anything you want. Our Knoevengel reaction requires 200ml of toluene for every mole of benzaldehyde, or 5000ml for every reaction.

4.3 Production of 1-phenyl-2-nitropropene

Set up the 22-liter RB in the heating mantle. Add 10-20 PTFE(Teflon) boiling stones to the vessel. Through the wide center neck, add 5000ml of toluene, 2500ml of benzaldehyde, and 1875ml of nitroethane, in that order, with stirring. Have the fitting reducer, Dean-Stark trap, and a West condenser greased up and assembled nearby. We will need to assemble the pieces quickly once the n-butylamine is added. Using a wooden dowling rod as a stirrer, quickly add 550ml of n-butylamine with stirring. The reaction mixture will turn from clear to a milky consistency as a Schiff's base and a molecule of water are formed(the water turns the solution milky). Assemble the fitting reducer, the Dean-Stark trap, and the West condenser on top of each other and plug the two side necks. Attach a fitting to the top of the condenser and run an exhaust line into your fume cabinet. Start the water running through the condenser. Wrap some aluminum foil around the top half of the reaction vessel and the Dean-Stark trap to avoid excessive cooling.

Turn on both heating elements and set the temperature controls at 20%. At this setting it will take a long time to heat up the solution. After one has some experience with this reaction, one can start out with the heating mantle at a higher setting(70% for 20min on my rig). One must be aware that we are using only a small West condenser for cooling and that it takes very little extra heat to blow material out the top. On my equipment, the proper setting is 18%--20% is too hot. Be very careful with the heat. The idea here is to boil the solution just hard enough to reach the bottom of the condenser where the water-toluene azeotrope can condense out into the Dean-Stark trap and be removed from the reaction solution. This occurs at 85°C.

Once the reaction reaches the condenser, the water will begin to accumulate rapidly. For a 25 mole reaction, 25 moles of water will be created and must be removed for the reaction to reach completion. This writer's Dean-Stark trap holds 25ml of water, resulting in a total of 18 full water-traps to complete a 25-mole reaction. Use a piece of paper and make a mark every time the trap is emptied. The water will come over rapidly at first, taking only a few minutes to fill the trap, and then slows down as water molecules get harder to find. The reaction should take about five hours to complete, but one should not use time as a definitive indicator. One will do much better at judging the quality and state of one's reaction by observing the color of the reaction mixture. As the water is removed, the solution will begin to turn a light orange color and deepen as the reaction nears completion. The use of too much catalyst, n-butylamine, will cause the reaction to polymerize to some degree, resulting in a dark brown solution color, poor quality nitropropene crystals, and a greatly reduced yield. Unfortunately, this reaction is very sensitive to the quantity and quality of the catalyst. Too little catalyst will reduce the yield significantly and too much will burn(polymerize) it. This writer advises that one do test batches of 1 and 5 moles in order to home in on the exact amount of n-butylamine required. If the reaction is allowed to continue once all the water is removed, it will begin to polymerize, so one should carefully watch the color of the reaction solution and keep careful track of the amount of water removed. Even if all of the theoretical amount of water has not been removed, if the solution color starts turning dark, pull it. Turn off the heat, allow the boiling to subside into the vessel, remove the condenser and Dean-Stark trap, then carefully lift the vessel out of the heating mantle and place it on a plastic bucket inside the fume cabinet. Leave it to cool down to room temperature overnight.

We will now strip the toluene solvent from the solution by performing a vacuum distillation. One needs a high-volume adjustable vacuum source in order to perform this distillation. Do not use a vacuum pump to strip solvents-it's hard on the pump and poses a high fire hazard. Always use an aspirator when vacuum-distilling solvents. Your typical university aspirator that runs off 40psi of water pressure is not adequate to pull a decent vacuum in a large volume, let alone an adjustable vacuum. We will be working with a system volume of about 27 liters. Attach two West condensers in series and support them carefully with tri-grips or wooden blocks with grooves cut into the tops. Attach a 5000ml round-bottom flask that has been marked at the 5000ml level. We will use this mark to determine when we have finished. Once completely assembled, turn on the heating mantle and set the controls at 30%. Once again, the reader's system/equipment will be slightly different from mine and he must make some minor adjustments. The idea here is to distill off the toluene at a temperature high enough to allow the condenser to liquefy the toluene so it doesn't get sucked into the vacuum system where it can cause damage. About 26-27"Hg or thereabouts will produce a distillation temperature range of about 40-60°C, which is hot enough to be condensed out by water at 10°C. One should not attempt to distill off the toluene at a normal atmosphere because the added heat quickly polymerizes the product as the toluene is removed. One must also make sure one has removed ALL of the toluene; even a small amount will prevent the crystals from forming or will produce poor quality crystals that polymerize rapidly in the open air. Since we started with 5000ml of toluene, we need to strip off at least that much. Use a mark on the receiver.

Once the toluene has been stripped off, turn off the heat, disassemble the equipment, and then pour the hot, orange liquid remaining in the vessel into two 5-liter plastic buckets, filling each of them to about 1/3 full and then covering. Quickly rinse and wash the big reaction vessel with methanol before the residue adheres to the walls. Let the liquid nitropropene cool for a few hours, then cover and place at the bottom of the freezer overnight. In the morning, the crystals will be formed and we must remove any unreacted material and contaminants. To accomplish this, pour about one liter of methanol which has been frozen for a week or two into one of the buckets holding the solid mass of crystal and break up the mass with a big screwdriver. The yellow nitropropene crystals are only slightly soluble in cold methanol, but the undesireable reaction remnants are very soluble, so we will dissolve the gunk while leaving the crystals intact. Once converted into a slurry, filter through a Buchner. Do the same to the other bucket. Empty the bright yellow crystals into a large cake tray and let them dry. Once dry, place into a 5gal bucket, cover, and place in the deep freeze. Left in the open air, the nitropropene crystals will polymerize in about one month. Stored in the freezer, these crystals will keep nicely for at least two years.

The yield on this reaction is not 100%, as stated in other literature. The theoretical yield is 79%, but the best this writer has achieved is 74%, with 70% being the average. Since one mole of 1-phenyl-2-nitropropene weighs 168g, one should end up with 25 moles x .7, or 17.5 moles of nitropropene crystals which weigh about 2940g. This writer advises that the chemist make and store all of his yellow nitropropene crystals before proceeding to the next step.

The chemist may wish to experiment with other strong bases in order to find an alternative to n-butylamine, which is rare enough to be a choke point.

4.4 Reduction of 1-phenyl-2-nitropropene to 1-phenyl-2-propanone

4.4.1 Equipment construction

This procedure is the most difficult described. Not because the reaction is difficult to perform, but because of the equipment one must build in order to make it workable. The problem is one of scale; A two-mole reduction can be performed in 5000ml glassware using a heating mantle and standard stirring equipment. To reduce a 20-mole batch requires ten times the volume, 50 liters, a controllable heat source, and scaled-up stirring equipment. Additionally, we will perform a steam-distillation in order to extract and purify the final product, which will require a large condenser. We will want this condenser to also operate in the reflux mode during the reaction in order to keep the acid from boiling off and killing everything. To make matters worse, we will be working with 15 liters of muriatic acid, which means everything must be made of stainless-steel. Fortunately, this equipment is neither difficult nor expensive to construct. One needs to either own and be proficient with a TIG welder or find a shop that can do the work. If one must use shops, spread the work around. They will all ask what it's for-simply tell them that you have a non-disclosure agreement and would lose your job or contract if you told them. Or make up your own story.

Our reaction vessel will be a 50-liter stainless stock-pot found at the kitchen/restaurant supply. It must be stainless, and not aluminum. High-quality stainless pots have aluminum-clad bottoms for better heat transfer-this is good. They will all be fabricated of thin-wall stainless, but look for the most heavy-duty pot you can find. This pot is the weak point in our equipment because the boiling hydrochloric acid will eat through the wall of the pot in 5-7 reactions, after which a new pot must be purchased.

In order to seal the pot, a flange must be welded onto the pot rim and provision made for attaching and sealing a top. This is done by carefully measuring the diameter of the pot rim and fabricating a flange to fit. We will be using a 3/16" polypropylene "O" ring for a seal and a series of bolts on the outside to accomplish the sealing and attaching. The ring should be about 2" wide, with the bolts(3/8" stainless hardware) on the outside and a 1/16" x 3/16" groove machined into the flange face about ¾" from the inside rim. Polypropylene O-ring material can be found at most good hydraulics shops and machine shops. We will be using 1/8" diameter or 3/16" diameter O-ring material, whichever is available. Buy enough for several rings, as they wear out. Our flange must also be flat to within 1/16" so the top isn't warped. Do not weld the flange to the pot until the top-plate has been fabricated.

We also have a requirement for knowing the temperature of the reaction at all times. In order to do this, one must either weld a stainless bushing into the side of the pot that fits an industrial thermometer or create a fitting in the top through which one can insert a thermometer long enough to reach the reaction solution. Good luck finding a thermometer that long. This writer chose the bushing-in-the-side method with mixed results-the temperature indication worked great but the boiling acid eats the thermometers and the bushing weld creates a weak point which the acid attacks and eats through after only three reactions. Covering the weld completely with fast-drying J-B Weld after each use doubled the lifespan of the pot to six reactions. I'm sure someone out there can think of something better. A Teflon- coated pot would be nice.

Now that we have the beginnings of a reaction vessel, we will need a heat source. Fortunately, one can find propane- powered barbeques almost anywhere, including the heavy-duty one pictured, which is more than adequate. A 30lb propane tank is good for about three reactions.

Now we must design our top-plate, which is fairly complex. The first step is to have a matching circle of 3/16" thick stainless-steel cut and drilled to fit the flange so they can be bolted together. Next, we must provide for a Teflon bearing in the middle. This writer designed a bearing machined from 3" Teflon round stock. Since the gearmotor used to turn the stirrer has a ½" driveshaft, the bearing consisted of a ½" hole in the middle and a ¾" wide outside shoulder machined down to ½" depth. This results in a ½" thick bushing wall, which has held up without problem. Using these dimensions, a center-hole of 1.5" diameter and four 10-32 threaded holes on the outside rim are required. It is advisable to have the Teflon bushing machined first and then fitted to the top. A shaft clearance of 0.003-5 works well. Unfortunately, one must know the diameter of the motor driveshaft in order to design the bearing. Many motors have 5/8" driveshafts which will operate perfectly with the above bushing design by simply enlarging the center hole, leaving a 3/8" bushing wall. The stirring shaft should be standard 316 stainless round stock with a flat machined at one end to make attaching the vanes easy.

The importance of vigorous stirring cannot be overemphasized. If too much iron remains on the bottom, it can cause a runaway reaction, which you will regret. To avoid this, keep the iron in suspension and the reactants moving. This writer has determined experimentally that about 150 rpm is a good speed for stirring, but this can vary depending upon the effectiveness of the stirring vanes. The vanes on the reaction vessel shown were a simple plate welded onto the bottom of the shaft, insuring that it did not contact the thermometer shaft inserted through the pot wall.

Now that we have a bearing and driveshaft, we must design a bracket that will hold our gearmotor firmly in line with the bearing and driveshaft. The picture above shows the gearmotor without the bracket, as the unit has been disassembled for storage. The reader will be left to his own devices in this bracket design since there is little chance that your gearmotor will be exactly like mine. Since there are two more attachments which must be placed on the top cover, one should locate an adequate gearmotor early on in the design and then wait until the end to fit the motor and bracket. The motor should have a shaft speed of about 150 rpm and a torque of 32 inch-pounds or better, keeping in mind that the more reaction mixture being turned, the more torque is required.

A 2" stainless nipple must be welded to the top plate to accommodate the condenser and it's fittings. In addition, a threaded ¼" hole must be placed in a location near the outside of the top plate. A ¼" NPT stainless nipple screws in here and is attached to 5/16 Tygon tubing leading to the acid reservoir. This is where the acid enters the reaction vessel.

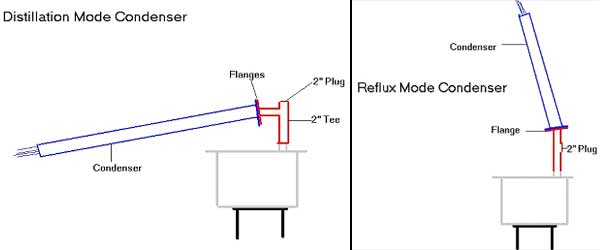

The condenser and its fittings are fairly straightforward. Four 5' sections of ½" thinwall stainless tubing are grouped within a 2" diameter circle and welded into a flat flange with outside boltholes. Use ½" bolts for strength and a thick rubber gasket. The outside waterjacket is 4" thinwall truck exhaust tubing which is light and cheap. It is fitted with ¼ " NPT bushings at each end for water circulation. It is sealed at the end with another flange, leaving 6-9" of tubing sticking out the end. The waterjacket should be 4' long. Use dishwasher hoses found at the hardware store that have ¼" NPT thread on one end and hose thread on the other for circulating water through the system. The condenser will need to be supported with chains due to it's weight when full of water. In order to use the condenser in both distillation and reflux modes, another flange must be fabricated which can be moved around in combination with standard pipe fittings. A combination of 2" stainless "T" , a 2" plug, and a 6" long nipple with an angled flange of about 20°C on the end worked well for this writer. The adapter flange must mate well with the condenser flange to avoid leaks.

The following diagrams show how the condenser is configured for both distillation and reflux modes:

A container to hold and dispense the muriatic acid is required. This writer uses a small(5gal) plastic garbage can with a Tygon tubing siphon hole drilled just above the acid line. A 1/8" stainless-steel flow valve is required to control the flow of acid into the reaction. These valves may be found at industrial supply houses like W.W. Grainger, etc. One should use only Tygon tubing as most other types will soon harden and crack.

4.4.2 Iron Reduction of 1-phenyl-2-nitropropene to 1-phenyl-2-propanone

Pour 15 liters of clean tap water into the vessel. Follow this with 4000g of catalytic iron, 3400g (20mol) of 1-phenyl- 2-nitropropene and 40-50g of ferric chloride. Assemble the top with the condenser in the reflux mode, start the water running through the condenser, begin stirring, and fire up the propane burner. Watch the thermometer and turn off the heat when the temperature reaches 90°C. Slowly add muriatic acid in small doses over a 2-hour period. Watch the top of the condenser for signs things are getting out of hand. This reaction needs to be performed in a small shed or other outbuilding with good ventilation. Install a heavy-duty (500+cfm) exhaust fan in the shed. The reason for this is that the fumes from this reaction are very corrosive and if the reaction goes into runaway, one will want to abandon the shed for awhile as the fumes clear out. A total of 15 liters of muriatic acid is added. Once all of the acid has been added, allow the stirring to continue for another 2 hours before going on to the next step.

We now must extract our P2P from the nasty black mess inside the reaction vessel. We will do this through steam distillation. Disconnect the condenser, flange, and "Tee", leaving the 2" nipple open. The stirrer should remain turning. Next, quickly pour in about 4 liters of saturated lye solution that has cooled off overnight. Some heat and steam will be generated as the lye neutralizes the muriatic acid. Assemble the Tee, flange, and condenser in the distillation mode and start the water flowing through the condenser. Place a 20 liter bucket under the end and fire up the propane burner to high. Discontinue stirring. Distill over the water and P2P until the bucket is full, then turn off the heat.

The yield for this reduction is 75% no matter how badly one thinks he has blown it, so we should expect to obtain 15 moles, or a little over 2000g of P2P. Since P2P has a density close to that of water, this works out to about 2 liters of product.

We must now extract the P2P from the water, purify it, and store it for later use. This is accomplished by pouring 3000ml of water/P2P into each of two 4000ml separatory funnel. One then adds about 300ml of saturated lye solution to each and shakes vigorously for 3-5 minutes. This is done to insure there is no residual acid which can, and will, poison the catalyst when used. After a thorough shaking, 400ml of methylene chloride is added to each separatory funnel and shaken vigorously for 2-3 minutes. Methylene chloride is an easily obtainable solvent for most plastics. Check the plastics supply shops that sell buckets, sheet plastic, etc. Since methylene chloride is heavier than water, it will pick up the P2P and carry it to the bottom of the sep funnel. This takes some time, however, so one must not get in a hurry. This writer allows the separation to sit for 6 hours before draining the bottom layer into a one-gallon wine bottle, or even better, an amber glass bottle. Cut a square out of a plastic baggie and use it for a seal between the bottle-top and the cap. Add another 400ml of methylene chloride, shake vigorously, and let it settle out again for 6 hours before draining. This is good enough, go on to the next batch. When finished, one should have 3-4 gallons of methylene chloride/P2P solution.

We will now recover our methylene chloride solvent for reuse and distill the P2P. Use a 5000ml round-bottom vessel and distill over the methylene chloride from 39 to 60°C. Return the solvent to it's container and continue until there is only about 2000ml of P2P left in the vessel. Add boiling stones and vacuum distill over the remnants of the methylene chloride and water until it is clear that only P2P is left. Using a clean receiver and fresh boiling stones, distill over the P2P at 105-115°C. Do not distill at a temperature lower than 105°C or the P2P will carry contaminants over with it, the contaminants being darker colored. P2P is a clear, pale-yellow liquid that smells like cat piss. P2P will auto- oxidize over a period of weeks if left at room temperature, so put it in the freezer until ready for use.

One can use toluene to extract the P2P from the water, but it must be vacuum-distilled and the separation will be to the top instead of the bottom like methylene chloride. It takes about the same amount of time to separate as when using methylene chloride.

4.4.3 Alternative reduction procedure

For those unable or unwilling to construct the admittedly large number of mechanical items described above, there is an alternative reduction procedure that the reader may or may not find more convenient. This reduction, gleaned from Dr. Alexander Shulgin's wonderful book PIKHAL, uses glacial acetic acid instead of muriatic acid to create hydrogen by reacting with catalytic iron. It also cleans up with water and eliminates the steam distillation step used above. The downside is that, as described, it takes a much larger volume of acid to reduce an equivalent amount of nitropropene. It may be possible to reduce the amount of acid required, and I leave it those interested to develop it further.