RDX: Various informations from Meyer & Kohler, and from The Preparatory Manual of Explosives.

Also random synth methods, etc

cyclo-1,3,5-trimethylene-2,4,6-trinitramine; Hexogen;

Trimethylentrinitramin; hexog`ene; RDX; T 4

Description: colorless crystals

Empirical formula: C3H6N6O6

Molecular weight: 222.1

Energy of formation: +96.0 kcal/kg = +401.8 kJ/kg

Enthalpy of formation: +72.0 kcal/kg = +301.4 kJ/kg

Oxygen balance: –21.6%

Nitrogen content: 37.84%

Volume of explosion gases: 903 l/kg

Heat of explosion

(calculated*)

(H2O liq.): 1350 kcal/kg = 5647 kJ/kg

(H2O gas): 1266 kcal/kg = 5297 kJ/kg

Heat of detonation**)

(H2O liq.): 1510 kcal/kg = 6322 kJ/kg

specific energy:

140 mt/kg = 1375 kJ/kg

Density: 1.82 g/cm3

Melting point: 204 °C = 399°F

Heat of fusion: 38.4 kcal/kg = 161 kJ/kg

Lead block test: 480 cm3/10 g

Detonation velocity, confined:

8750 m/s = 28700ft/s at r = 1.76 g/cm3

Impact sensitivity: 0.75 kp m = 7.5 N m

Friction sensitivity: 12 kp = 120 N pistil load

Critical diameter of steel sleeve test: 8 mm

Cyclonite is soluble in acetone, insoluble in water and sparingly soluble

in ether and ethanol. Cyclohexanone, nitrobenzene and glycol are

solvents at elevated temperatures.

Cyclonite is currently probably the most important high-brisance explosive;

its brisant power is high owing to its high density and high

detonation velocity. It is relatively insensitive (as compared to, say

W PETN, which is an explosive of a similar strength); it is very stable.

Its performance properties are only slightly inferior to those of the

homologous W Octogen (HMX).

The “classical” method of production (Henning, 1898) is the nitration of

hexamethylene tetramine (C6H12N4) to “Hexogen” (C3H6O6N6) using

concentrated nitric acid; the concentrated reaction mixture is poured

into iced water, and the product precipitates out. The structural formula

shows that three methylene groups must be destroyed or split off by oxidation. As soon as this problem and the attendant dangers had

been mastered, industrial-scale production became possible, and during

the Second World War Cyclonite was manufactured in large quantities

on both sides, using several mutually independent chemical

methods.

S-H process (inventor: Schnurr): continuous nitration of hexamethylenetetramine

using highly concentrated nitric acid, accompanied by a

decomposition reaction under liberation of nitrous gases, without destruction

of the Cyclonite formed. The reaction mixture is then filtered

to separate the product from the waste acid, followed by stabilization

of the product by boiling under pressure and, if required, recrystallization.

K process (inventor: Knöffler): an increased yield is obtained by the

addition of ammonium nitrate to the nitration mixture of hexamethylene

tetramine and nitric acid, followed by warming. The formaldehyde as a

by-product forms more hexamethylenetetramine with the added ammonium

nitrate and is converted by the nitric acid into Cyclonite.

KA process (inventors: Knöffler and Apel; in USA: Bachmann): hexamethylenetetramine

dinitrate is reacted with ammonium nitrate and a

small amount of nitric acid in an acetic anhydride medium. Cyclonite is

formed in a similar manner as in the E process. The waste acetic acid

thus formed is concentrated, subjected to the so-called ketene process,

recycled, and the regenerated acetic anhydride is re-used.

E process (inventor: Eble): paraformaldehyde and ammonium nitrate

are reacted in an acetic anhydride medium with formation of Cyclonite

(precursor of KA process).

W process (inventor: Wolfram): potassium amidosulfonate and formaldehyde

are reacted to give potassium methyleneamidosulfonate (CH2

= N-SO3K), which is then nitrated to Cyclonite by a nitric acid-sulfuric

acid mixture.

Phlegmatized and pressed Cyclonite is used as a highly brisant material

for the manufacture of W Booster and W Hollow Charges. Nonphlegmatized

Cyclonite in combination with TNT is also used as a

pourable mixture for hollow charges and brisant explosive charges

(W Compositions B); mixtures of Cyclonite with aluminum powder are

used as torpedo charges (Hexotonal, Torpex, Trialen). Cyclonite may

also be used as an additive in the manufacture of smokeless powders.

In manufacturing explosive charges which are required to have a

certain mechanical strength or rubber-elastic toughness, Cyclonite is

incorporated into curable plastic materials such as polyurethanes,

polybutadiene or polysulfide and is poured into molds (W Plastic Explosives).

Specifications

melting point: at least 200 °C = 392°F

for products prepared

by the acetic anhydride

method, at least 190 °C = 374°F

acidity, as HNO3:

not more than 0.05%

acetone-insolubles:

not more than 0.025%

ashes: not more than 0.03%

sandy matter: none

RDX forms orthorhombic crystals with a melting point of 206 Celsius. 1 Gram dissolves in 25 milliliters of acetone, but its solubility in alcohol, ether, ethyl acetate, and glacial acetic acid is even less. It is insoluble in water, carbon tetrachloride, and carbon disulfide. RDX is one of the most important military explosives known to man. It is highly versatile, being resistant to heat, shock and percussion, and is capable of being alloyed with many different secondary explosives. RDX is very well known in several of the most important explosives compositions. These compositions include: semtex, C4, and composition B, all of which are widely used in military operations. RDX is by far one of the most important explosives in occurrence, and it is manufactured on an industrial scale.

SYNTH 1:

Reagents NEEDED:

22.6 grams DAPT

13.6 grams glacial acetic acid

21 grams ammonium nitrate

26.2 grams of 70% nitric Acid

60 grams acetic anhydride

PROCEDURE:

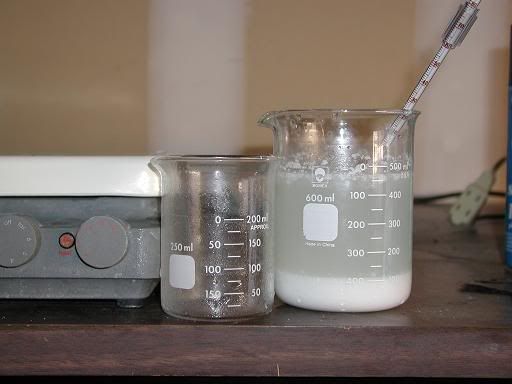

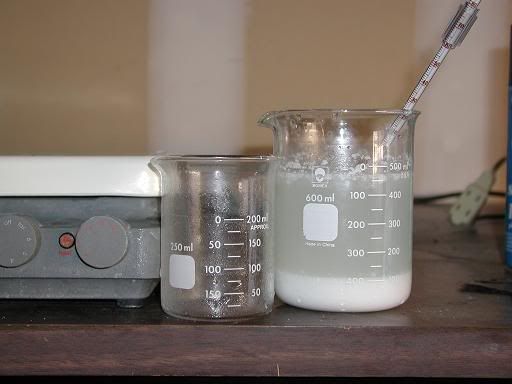

Into a 200-milliliter beaker add 13.6 grams glacial acetic acid, and then add and dissolve 22.6 grams of DAPT. Afterwards, pour the contents of the 200-milliliter beaker into a round bottom flask and then assemble the apparatus illustrated in figure 040. After which, prepare a solution by dissolving 21 grams of ammonium nitrate into 26.2 grams of 70% nitric acid, and then place this solution into one of the dropping funnels attached to the round bottom flask. Then add 60 grams of acetic anhydride to the second dropping funnel. Then slowly add the two solutions from the dropping funnels, drop wise. During the additions keep the reaction temperature below 68 Celsius (this is done by slow addition of the two liquids). If the temperature of the reaction mixture goes above 68 Celsius, stop the additions and allow the mixture to cool in a cold water bath (Note: The addition sequence is started with the nitric acid/ammonium nitrate solution and is followed by the acetic anhydride. In other words, the nitric acid/nitrate solution is added in a small portion first. After a couple of seconds some of the acetic anhydride is added. This cycle of addition of reactants is continued until both liquids have been added to the reaction mixture). An initial unknown precipitate forms almost from the first addition of the nitric acid/ammonium nitrate solution. The precipitate will then re-dissolve, and the solution clears. The solution remains clear until about two-thirds of the additional reactants are added. A second precipitate now forms which is RDX. As the additions proceed, the RDX precipitate will become noticeably greater. After the addition of the nitric acid/ammonium nitrate solution and the acetic anhydride, place the reaction mixture into a cold water bath and cool to room temperature. Afterwards, stir the mixture for 20 minutes at room temperature and then filter-off the precipitated RDX product, wash with 500 milliliters of cold water, and then vacuum dry or air dry. The dried RDX will have a high purity.

SYNTHISES OF DAPT (precursor to RDX):

Reagents needed:

1960 grams of hexamine

1060 grams acetic anhydride

Procedure:

To a 4-liter container place 1960 grams of hexamine. Then add 1960 milliliters of cold water, and then stir the mixture rapidly for 1 hour. After 1 hour, place the 4-liter container into an ice bath, and cool the 4-liter flask to 0 Celsius. Afterwards, add 980 grams of ice, and then rapidly add 1060 grams of acetic anhydride over a period of about 1 minute while rapidly stirring the reaction mixture, and maintaining its temperature at 0 Celsius at all times. After the addition of the acetic anhydride, continue stirring at 0 Celsius for 10 minutes. After 10 minutes, place the entire reaction mixture into a distillation apparatus and distill at 140 Celsius for 4 hours. After 4 hours, remove the heat source and allow the reaction mixture to cool to room temperature. Then filter-off the precipitated DAPT, wash with 400 milliliters of cold water, and then vacuum dry or air dry.

SYNTH 2 FOR RDX:

Reagents Needed:

20 grams 1,3,5-tripropionylhexahydro-s-triazine

400 milliliters 99% nitric acid

Procedure:

Note: In this procedure, an excessive amount of nitric acid is used to properly carryout the procedure. This nitric acid can be easily recycled for a another crop of RDX by adding an additional 10 milliliters of 99% nitric acid to the reaction mixture (after removal of the previous RDX product), followed by adding an additional 20 grams of 1,3,5-tripropionylhexahydro-s-triazine—carryout this procedure using the same technique as in the following (original) procedure.

Add 400 milliliters of 99% nitric acid to a suitable flask, and then cool to about 20 Celsius by means of a water bath. While maintaining the temperature of the nitric acid at about 20 to 25 Celsius, slowly add 20 grams of 1,3,5-tripropionylhexahydro-s-triazine over a period of 80 minutes while constantly stirring the acid. After the addition of the 1,3,5-tripropionylhexahydro-s-triazine, heat the mixture to 70 Celsius while stirring for 3 hours. After 3 hours, remove the heat source and allow the mixture to cool to room temperature. Afterwards, add the entire mixture to 1000 milliliters of cold water, and then filter-off the precipitated RDX, wash with several portions of cold water, and the vacuum dry or air-dry the RDX. The result will be 13 grams of high purity RDX.

Thats all the data I could be bothered compiling. I have two other synths I will rip and post later for RDX.

COMING SOON...

New write ups on the 'new detonator systems' project.

Hexamine Dinitrate synth.

Upload of 'Fedoroff' to the FTP.

The urea nitrate (1kg batch – method by Rosco Bodine) and Nitrourea methods coming soon.

After that comes Azides, more on AP, and some interesting primary explosives...

Sorry for the inconvenience.

Sorry for the inconvenience.  .

.